Industrial Jaggery Sugar Production Machine 250 kg/h

Material:

Sugar, powdered sugar, water, etc

Capacity:

250 kg/h

Loading Port:

Qingdao Port

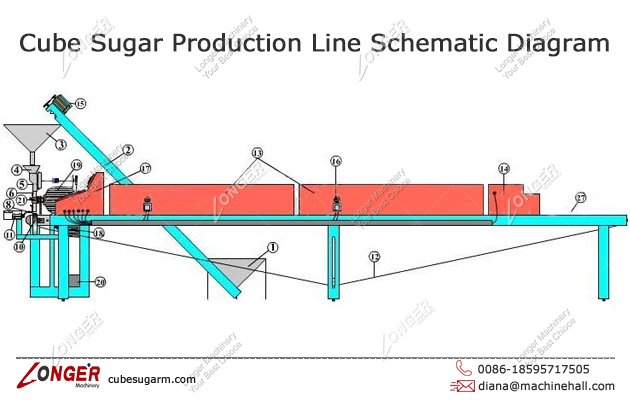

Cube Sugar Manufacturing Process

First, grinding sugar into needed fineness sugar powder, then mixing and feeding the grinder sugar powder and sugar into the cube sugar forming machine through spiral feeding machine, after the hydraulic pressure cube sugar making machine, to achieve desired cube sugar, then convey cube sugar to drying tunnel by tablet linkage conveyor to remove excess water for late packaging and storage; After the drying tunnel, cube sugars need cooling, and then packing into carton, box or bags according to different demand.

The cube sugar manufacturing plant include sugar grinding machine, mixed spiral feeding machine, sugar cube molding machine, tablet linkage conveyor, drying tunnel, cooling machine and cube cube packaging machine. High quality stainless steel conforms to food standards. Cube sugars are popular among people all over the world and sugar making equipment become increasingly popular in different countries.

Note:

Note:

1, Different shapes of cube cube can be made by changing forming mould;

2, Different raw materials, production capacity will be a little different;

3, According to different materials, match stir feeding machine, infrared drying oven, plate interlocking machine conveyor, cube sugar forming machine, automatic packaging machine, printer and other supporting device, bring into line production.

|

No.

|

Equipment Name

|

Specifications

|

|

1

|

Sugar Grinder

|

GG-300

Capacity:100-300kg/h Feed size: <5mm Grinding fineness:12-150mesh Motor power:3kw Dimension:780*750*1500mm Weight:250kg |

|

2

|

Mixed Spiral Feeding Machine

|

Model: GG-SG

Motor power: 3.85kw Dimension: 500*500*1650mm Weight: 240kg |

|

3

|

Sugar Making Machine

|

Model: GGF-90 Capacity:250kg/h Power:3kw,380V/50Hz Dimension:1900*750*1750mm Weight:800kg |

|

4

|

Tablet Linkage Conveyor

|

Model: GGS-2

Efficiency: 0-10m3/min Air pressure: 0.3-0.5Mpa Dimension: 1300*700*1000mm Weight: 60kg |

|

5

|

Infrared Drying Tunnel

|

Model: GGH-3

Efficiency: 0-10m3/min Power: AC380V50Hz 2KW*6 Dimension: 1900*700*1150mm Weight: 90kg*6 |

|

6

|

Cooler Machine

|

Model: GGQ-1

Function: Cooling Efficiency: 0-10m3/min Dimension: 1900*700*700mm Weight: 60kg |

|

7

|

Semi-automatic Sugar Packing Machine

|

Model: GG-250

Voltage: 220V/380V 50-60Hz Power: 2.2kw Table: customized Chuck handle: 2 pcs Dimension: 650*600*950mm Weight: 75kg |